uhmw friction coefficient

Download scientific diagram Coefficients of friction of various UHMWPE materials. 180 Heat deflection temperature 264 psi F.

Ceramic On Uhmwpe Pair Friction Coefficient Profiles Over Time At 15 Download Scientific Diagram

Redco UHMW is proven to outlast mild and hardened steel by as much as 10 to 1.

. They do not degrade or rot and are easily recycled at the end of their useful service life. The fabricfabric interply friction and fabrictooling friction is evaluated over a range of contact pressures material orientations and sliding. Wear Factor K x 10-10.

M2 weight of conveyed objects f1 coefficient of friction when chain etc are returning f2 coefficient of friction when chain etc are conveying f3 coefficient of friction when conveyed objects are moving g gravitational constant 11 sprocket losses due to directional changes of the chain. Coefficient of friction against hardened and ground steel P 005 Nmm2 v 06ms 029 - - Ball indentation hardness 35 MPa 2039 -1 Shore hardness D 64 - 868 Thermal Properties Value Unit DINENISO Glass transition temperature - C 537 36 Crystalline m elting point 135 C 537 36. The friction coefficient of the chain guide is small only 007-011 and it has good self-lubrication.

Properties of UHMW. Maximum Static Bearing Load P PTM55007. Features Very low friction coefficient Excellent abrasion resistance UV and ozone resistant Does not rot split or crack 100 recyclable Applications Fender panel frame face pads.

Water absorption immersion 24 hours D570. D648-250 - Maximum continuous service temperature in air F. 50 rows Coefficient of Friction Dry vs Steel Dynamic.

The mean coefficient of friction of the UHMWPE-on-PEEK and UHMWPE-on-cobalt chrome bearing couples with respect to increasing protein concentration is shown in Fig. Good non-adhesiveness easy to clean the surface adhesion. Maximum Unlubricated No Load Bearing Velocity V PTM55007.

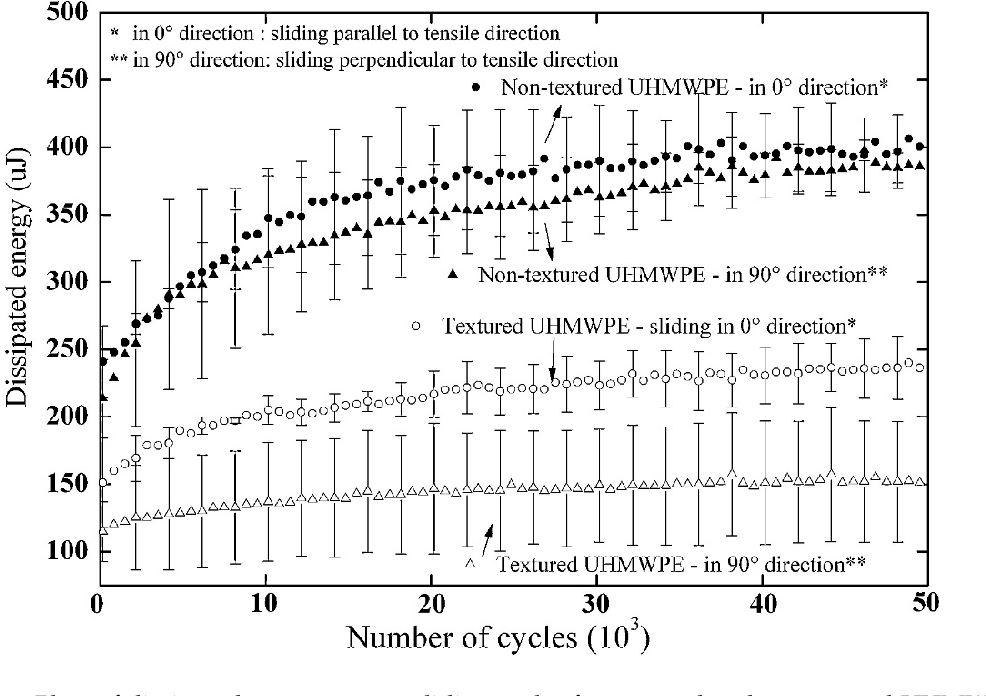

Typical properties of UHMW UNITS ASTM TEST UHMW-PE. M1 weight of the chain etc. This paper deals with the friction coefficient behaviour during dry reciprocating sliding of UHMWPE in contact with alumina Al2O3 within a.

Thermal Expansion Coefficient. The friction coefficient between the object and the surface is 062. 87 rows Coefficient of Friction.

The high molecular weight is what gives UHMW-PE a unique combination of high impact strength efficient of friction and abrasion resistance that outwears carbon steel 10 to 1 making it more suitable for applications where lower molecular weight grades fail. Starwheels bushings bumpers chain guides wear stripes wear plates Sprockets guide rails. Maximum Limiting PV Unlubricated PTM55007.

Water absorption immersion 24 hours D570. PTFE can only handle about 15th the load of UHMW PTFE is more slippery than UHMW despite both having a low coefficient of friction UHMW has far better wear properties than PTFE UHMW is typically stocked in 48 x 120 sheets where PTFE comes in 48 x 48 plates PTFE withstands over 4x the temperature UHMW can in continuous operation. I dont see HDPE friction listed in my sources so I was wondering if anyone in plastics would be able to provide it.

Sand Wheel WearAbrasion Test. The sources Im working with give a friction coefficient for UHMW of 14. Izod impact notched ft-lbsin of notch.

1 Nov 02 0839. The friction force can be calculated as Ff 062 100 lb 62 lb 1 lb 04536 kg Example - Car Braking Friction Force and Required Distance to Stop A car with mass 2000 kg drives with speed 100 kmh on a wet road with friction coefficient 02. Im mainly looking for the fricion coefficient of HDPE but I would like a second source for the friction coefficient for UHMW as well.

The steady friction coefficient of UHMWPE rubbing with the un-implantedTi6Al4V is approximately 02 while rubbing with sample no. The uhmw u channel stock guide rail has strong abrasion resistance and its abrasion resistance is 5 times that of nylon 66 and 7 times that of carbon steel. FQ1000 UHMW-PE materials are compounded to resist ozone and UV radiation.

Coefficient of linear thermal expansion. Coefficient of Linear Thermal Expansion. The reason is the large d ifference between the coefficient of thermal expansion of.

Coefficient of linear thermal. Two UHMWPE materials are selected including solid-state extruded film DuPont Tensylon 30A and fiber system Dyneema HB 210 and one tooling material Stretchlon 800 vacuum bagging film. Coefficient of Friction.

DETC2009-86365 Numerical Investigations of Mechanical Responses Friction and the Formation of. With increasing protein concentration above 2 there was a trend for decreasing friction for both material combinations. Heat deflection temperature 66 psi264 psi F.

It is odorless tasteless and nontoxic. 4 which was implanted with oxygen at the highest. The friction coefficients of UHMWPE rubbing with the two-step ion implanted Ti6Al4V alloys are much lower than those of rubbing with the un-implanted specimens.

D648-Maximum continuous service temperature in air F. UHMW MOLECULAR WEIGHT VISCOSITY GRAPH Its coefficient of friction is significantly lower than nylon and acetal and is comparable to PTFE with superior abrasion resistance.

The Friction Coefficient Of Uhmwpe Under Lubrication And Download Scientific Diagram

Coefficients Of Friction Of Various Uhmwpe Materials Download Scientific Diagram

Pdf Ultra High Molecular Weight Polyethylene Uhmwpe As A Promising Polymer Material For Biomedical Applications A Concise Review Semantic Scholar

Tapecase 230220 Uhmw Tape 34 X 5yds 1 Roll Natural

Uhmw Polyethylene Types Of Plastics Jig Polyethylene

Uhmw Polyethylene Types Of Plastics Jig Polyethylene

Uhmw Plastic Jig Stock 3 4 Thick

Friction And Wear Properties Of Pe Uhmw Modified With Nano Sio Sub 2 Sub And Pa6

Coefficient Of Friction Of Uhmwpe With Fillers Download Scientific Diagram

Pe Uhmw For Industry Wefapress

A And B Illustrates The Variation Of Friction Coefficient Values Of Download Scientific Diagram

Uhmw Plastic Jig Stock 3 4 Thick

Ultra High Molecular Weight Tubing

Friction Coefficient And The Static Mechanical Characteristics Of A Download Table

The Coefficient Of Friction Cof Of Uhmwpe For Different Aging Times Download Scientific Diagram

Uhwm Sheet Plastic Industry Henan Plastic Sheets

Polymers Free Full Text Ultra High Molecular Weight Polyethylene Uhmwpe As A Promising Polymer Material For Biomedical Applications A Concise Review Html

Ultra High Molecular Weight Polyethylene Reinforced Polypropylene And Polyamide Composites Toward Developing Low Noise Automobile Interior Lee 2020 Journal Of Applied Polymer Science Wiley Online Library

0 Response to "uhmw friction coefficient"

Post a Comment